Energy and Momentum

of Collisions

Relating

Momentum and Kinetic Energy to Can Deformation

Trip and Zach

Passenger Cart Collisions

(4/14/03-4/30/03)

Abstract

The

purpose of the passenger cart collisions was to use video imaging to analyze

inelastic collisions. This enabled us to develop or refute any relationship

between conservation of momentum and kinetic energy and can deformation from

the collisions of the carts. Our main results indicated that there definitely

was a relationship between can deformation and loss of kinetic energy in the

collisions.

Theory

The

underlying principals behind the actual collisions that took place existed in

the theories of conservation of linear momentum and kinetic energy and also in

can deformation magnitude. As a general assumption about the deformation of the

cans attached to the carts, we operated with two rules in mind when analyzing

our data: 1) the energy required to deform the can(s) is proportional to the

deformation and 2) that energy is also proportional to the square of the deformation.

The

theory for conservation of linear momentum in relation to our two passenger

carts is as follows:

m1v1 + m2v2

= m1v1’ + m2v2’

or

(m1v1 + m2v2)

– (m1v1’ + m2v2’) = 0

The theory

states that the product of an object’s initial mass and velocity added to that

of the second object’s initial state should equal the sum of the final values

(or “after-collision” state) of both objects.

With

respect to kinetic energy release, the following formula depicts how that value

is calculated:

Edeformation = Change

in KE

Change in KE = ABS[(½

m1v12 + ½ m2v22)

- (½ m1v12’ + ½ m2v22’)]

Thus, the

energy of deformation is equivalent to the change in kinetic energy from

initial kinetic to final kinetic states during the collisions.

Experiments

In

our experiments we used two students, two passenger collision carts with can

mounts, more than 150 cans for 18 trials (CAN FROM THE SAME MANUFACTURER), two

meter sticks, a scale, a camcorder, and VideoPoint video analysis software. The

experiment was setup up with a collision point (or reference point) picked at

an arbitrary location along a sidewalk. From this point, lines were drawn with

chalk the same distance away in opposite directions, and then one more set

another identical distance beyond that. This guide gave each cart pusher a

precise location of where to start pushing the cart and where to let go before

the cart and person coasted to the central collision spot. For each collision,

the passenger’s mass was noted and the deformation of the cans was measured

can-by-can and then tabulated.

For

each collision, the video camera recorded the people in it, the trial number,

and the collision itself. This video was then spliced and converted to 18

separate movies (one for each run), which were then burned to a CD and analyzed

with VideoPoint software. During the analysis, a crucial screen calibration of

a known distance was made. This known distance was the measured length from the

front to back wheels of a cart. After calibration, the video could be broken

down into the two objects and their tracked movement between all frames. This

ball-park selection method provided the data for which the rest of the

experiment was constructed upon.

Data Analysis

Taking

Measurements

The

actual data plots taken from the video recordings were applied by hand in a

“best-guess” fashion based on our ability to follow the same pixel through all

frames. Of these data plots, the ones we used to form our “initial” and “final”

calculations for velocity were located in sets of 4 or 5 points just before and

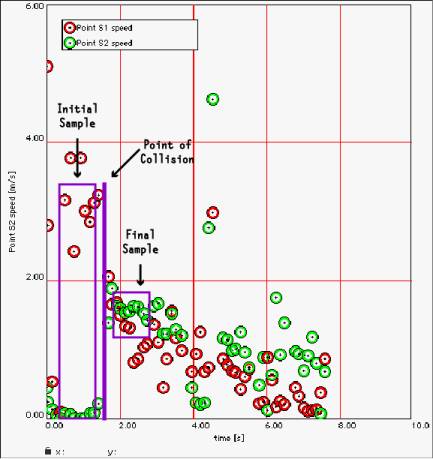

just after the collision, respectively, as illustrated in the following graph:

Figure 1: Run 2 (Trip Moving, Zach

Still) Velocity Plot

It

was easy to pick a collision point based on where the data points jumped up or

down to a new velocity value. From this location, one could project forward and

backward about five points to obtain an average value for both initial and

final velocity of the left and right carts.

Determining

Errors

Our

error determination came from comparing different measurements taken by each

person involved in their respective run. Four separate measurements were

analyzed for error: Vi left, Vi right, Vf

left, and Vf right. For example, the average values that I

calculated me for Run 2 were compared with Zach’s average values and the “plus

or minus error” for that particular measurement was just half of the difference

between each set of measurements. The following table shows the velocity errors

in their entirety:

|

PLUS/MINUS ERROR |

||||

|

Run |

Vi L |

Vi R |

Vf L |

Vf R |

|

1 |

0.25 |

0.15 |

0.27 |

0.05 |

|

2 |

0.26 |

0.10 |

0.19 |

0.03 |

|

3 |

0.27 |

0.28 |

0.13 |

0.09 |

|

4 |

0.40 |

0.03 |

0.07 |

0.07 |

|

5 |

0.00 |

0.25 |

0.01 |

0.13 |

|

6 |

0.38 |

0.21 |

0.36 |

0.26 |

|

7 |

0.00 |

0.48 |

0.14 |

0.12 |

|

8 |

0.00 |

0.00 |

0.00 |

0.00 |

|

9 |

0.15 |

0.32 |

0.04 |

0.07 |

|

10 |

1.43 |

0.00 |

1.00 |

0.91 |

|

11 |

0.00 |

0.08 |

0.72 |

0.24 |

|

12 |

0.29 |

1.05 |

0.53 |

0.01 |

|

13 |

0.00 |

0.00 |

0.00 |

0.00 |

|

14 |

0.43 |

0.30 |

0.10 |

0.04 |

|

15 |

1.10 |

0.23 |

0.26 |

0.28 |

|

16 |

0.23 |

0.33 |

0.44 |

0.60 |

|

17 |

0.39 |

0.88 |

0.07 |

0.12 |

|

18 |

0.08 |

0.40 |

0.14 |

0.95 |

Figure 3: Velocity Error Calculations

As

Figure 3 shows, our errors were as extreme as Ī 1.5 m/s and as small as Ī 0.01

m/s. However, on average, our error was normally between

Ī 0.1 m/s and Ī

0.5 m/s, which for all intensive purposes is acceptable for the level of

precision we could expect from the analog video camcorder we were using,

coupled with the manual data plotting in VideoPoint (Please see the external

Excel file for full access to the numbers used in the Figure 3 calculations). I

was important to note that Runs 8 and 13 were nullified due to a complete miss

in Run 8 and a crash in Run 13.

Examining

Conservation of Momentum

In

our experiment, it was necessary to use object mass (in our case it was just

the person’s mass since both carts were identical in mass) and calculated

average velocity to produce average values for momentum. Excel formulas were

used to extrapolate a value of momentum (P) for each side (left and right) and

for each state (initial and final). The following spreadsheet sample provides

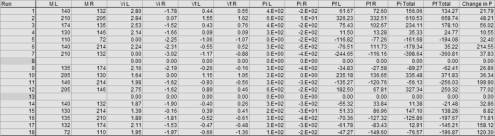

insight into how the momentum data was produced:

Figure 4: Average Momentum Value

Table

It

was clear from looking at Pi total and Pf total (the last

two columns) and then looking at Change in P (the last column) in Figure 4 that

conservation, although not proven with 100% accuracy here, was conserved. One

could assume that by looking at how large the values are for difference in

momentum that momentum might not be conserved. Below are the last three columns

in the Figure 4’s data table:

|

RUNS |

Pi Total |

Pf Total |

Change in P |

|

1 |

156.06 |

134.27 |

21.79 |

|

2 |

610.53 |

658.74 |

48.21 |

|

3 |

234.11 |

178.10 |

56.02 |

|

4 |

35.33 |

24.77 |

10.55 |

|

5 |

-161.68 |

-194.08 |

32.40 |

|

6 |

-179.34 |

35.22 |

214.55 |

|

7 |

-398.64 |

-360.81 |

37.83 |

|

8 |

0.00 |

0.00 |

0.00 |

|

9 |

-89.27 |

-62.41 |

26.86 |

|

10 |

335.48 |

371.83 |

36.34 |

|

11 |

-56.13 |

-256.03 |

199.90 |

|

12 |

327.34 |

250.32 |

77.02 |

|

13 |

0.00 |

0.00 |

0.00 |

|

14 |

11.38 |

-21.48 |

32.86 |

|

15 |

147.10 |

138.28 |

8.82 |

|

16 |

-125.86 |

-197.67 |

71.81 |

|

17 |

12.91 |

-145.21 |

158.12 |

|

18 |

-76.57 |

-196.87 |

120.30 |

Figure 5: Average Momentum

Calculations

However,

a larger Change in P was justified by larger values of momentum in most cases,

so the differences were all of the same proportions across all 18 runs. There were

exceptions to the trend (see Runs 6, 11, 17, 18) and these values were most

likely obtained because of systematic error in the way that the VideoPoint data

were manually plotted by the respective participants.

Examining

Conservation of Kinetic Energy

We

expected that there would be a loss

of kinetic energy (kinetic energy is released in the inelastic collision

through the crushing of the cans and also through friction). The following data

table illustrates our kinetic energy calculations based on our average value

velocities used to obtain momentum:

|

Ki L |

Ki R |

Kf L |

Kf R |

Ki Total |

Kf Total |

Change in Ke |

|

547.82 |

210.23 |

13.58 |

19.97 |

758.05 |

33.55 |

-724.50 |

|

846.89 |

0.49 |

253.39 |

269.67 |

847.38 |

523.06 |

-324.32 |

|

555.78 |

156.67 |

16.35 |

39.04 |

712.45 |

55.39 |

-657.06 |

|

296.84 |

201.36 |

0.51 |

0.60 |

498.20 |

1.11 |

-497.09 |

|

0.00 |

181.52 |

62.03 |

41.45 |

181.52 |

103.48 |

-78.04 |

|

352.41 |

568.94 |

20.91 |

29.17 |

921.35 |

50.07 |

-871.27 |

|

0.00 |

601.95 |

142.51 |

51.11 |

601.95 |

193.62 |

-408.33 |

|

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

|

313.47 |

415.36 |

4.49 |

2.19 |

728.83 |

6.68 |

-722.15 |

|

274.51 |

0.00 |

134.90 |

71.82 |

274.51 |

206.72 |

-67.79 |

|

286.98 |

279.08 |

62.67 |

34.07 |

566.06 |

96.74 |

-469.33 |

|

775.33 |

191.51 |

81.24 |

15.75 |

966.84 |

96.99 |

-869.85 |

|

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

|

245.44 |

238.21 |

10.93 |

4.34 |

483.65 |

15.27 |

-468.38 |

|

125.22 |

2.60 |

10.13 |

17.67 |

127.82 |

27.80 |

-100.02 |

|

239.93 |

344.50 |

18.33 |

38.59 |

584.43 |

56.93 |

-527.50 |

|

293.28 |

202.33 |

14.46 |

20.00 |

495.61 |

34.46 |

-461.15 |

|

136.47 |

213.56 |

15.52 |

101.73 |

350.03 |

117.24 |

-232.78 |

Figure 6: Average Kinetic Energy

Values

Our

assumption that kinetic energy was NOT conserved was correct because ALL values

of the change in KE were negative. It was evident that Ki

total was larger that Kf total in every case.

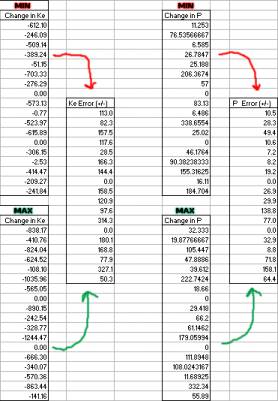

Analyzing

Error for Both Momentum and Kinetic Energy Change

In

both series of calculations, kinetic energy and momentum value for initial left

and right and final left and right were added to get initial and final totals

so that an overall value of change could be produced. The table below shows

minimum and maximum versions of these values; they were calculated from

subtracting and adding the plus/minus velocity errors to and from the original

average values to get two more tables of identical labels (See attached excel

file for complete calculations):

Figure 7: Min/Max-Generated Error for

KE and P

The

error in KE calculations was obtained by halving the absolute

difference of the min and max values; P error was reached in the same manner.

The KE error ranged from about Ī 50 J to Ī 300 J. The error for P

was anywhere from Ī 7 kg m/s to Ī 150 kg m/s. All runs were performed in at

least slightly different conditions, and at most at completely different

speeds. This fact accounts for the varying magnitude and value of the errors between

the runs and makes it irrelevant to compare them beyond the fact that they are

all in proportion to their respective values of momentum and kinetic energy, as

was explained in Figure 5.

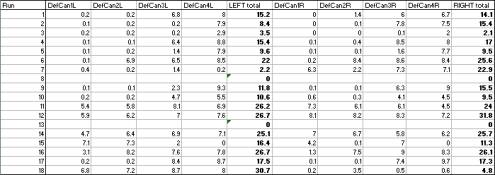

Relating Can

Deformation to Kinetic Energy Loss

All

can deformation values were measured in centimeters of defamation from a full

“normal” length of 10.4 cm. The following table shows the individual can

defamation values and then the TOTAL deformation in bold:

Figure 8: Can Deformations

We

observed that, for example, in Run 1, where both objects were moving at each

other at similar opposite velocities, the total deformation of the cans was

similar, too, in value. However, in Run 2 and others alike where one objects is

moving and hits another stationary

object with zero velocity, the deformation of the cans is drastically

different. To us this suggested that there was a direct, linear relationship

between the loss of kinetic energy and the magnitude of can deformation.

We

started out with total can defamations from the left and right, so it only made

sense to add left and right defamations to obtain a grand total to compare with

Change in KE. From our theory (See Page 1) we knew that defamation

was proportional to kinetic energy and kinetic energy squared. So in order to

create a graph that displayed a linear relationship, we would have to

experiment with the following mathematically-manipulated values of KE:

|

Run |

LEFT

total |

RIGHT

total |

TOTAL

Def |

Ke |

Ke^2 |

|

1 |

15.2 |

14.1 |

29.3 |

-724.5 |

5.2E+05 |

|

2 |

8.4 |

15.4 |

23.8 |

-324.3 |

1.1E+05 |

|

3 |

3.5 |

2.1 |

5.6 |

-657.1 |

4.3E+05 |

|

4 |

15.4 |

17.0 |

32.4 |

-497.1 |

2.5E+05 |

|

5 |

9.6 |

9.5 |

19.1 |

-78.0 |

6.1E+03 |

|

6 |

22.0 |

25.6 |

47.6 |

-871.3 |

7.6E+05 |

|

7 |

2.2 |

22.9 |

25.1 |

-408.3 |

1.7E+05 |

|

8 |

0.0 |

0.0 |

0.0 |

0.0 |

0.0E+00 |

|

9 |

11.8 |

15.5 |

27.3 |

-722.2 |

5.2E+05 |

|

10 |

10.6 |

9.5 |

20.1 |

-67.8 |

4.6E+03 |

|

11 |

26.2 |

24.0 |

50.2 |

-469.3 |

2.2E+05 |

|

12 |

26.7 |

31.8 |

58.5 |

-869.9 |

7.6E+05 |

|

13 |

0.0 |

0.0 |

0.0 |

0.0 |

0.0E+00 |

|

14 |

25.1 |

25.7 |

50.8 |

-468.4 |

2.2E+05 |

|

15 |

16.4 |

11.3 |

27.7 |

-100.0 |

1.0E+04 |

|

16 |

26.7 |

26.1 |

52.8 |

-527.5 |

2.8E+05 |

|

17 |

17.5 |

17.3 |

34.8 |

-461.2 |

2.1E+05 |

|

18 |

30.7 |

4.8 |

35.5 |

-232.8 |

5.4E+04 |

Figure 9: Comparing Total Deformation

to KE and KE2

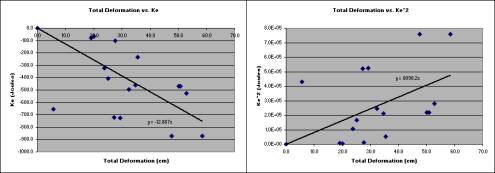

Once

we had the KE and KE2 values tabulated with

total deformation, we could set up a visual representation to see if indeed

there was or was not a linear relationship in our data:

Figure 10: Def. Total/KE

Graphical Analysis

The

graphical representation of the data when looking at total deformation versus KE

indicates a probable linear but indirect relationship. As total deformation of the cans increases,

the amount of kinetic energy gets increasingly negative (more is released).

When plotted against KE2, however, there is a linear but direct relationship. These graphs, although

there are some extreme outlier data points, do illustrate a pattern that

suggests a linear relationship.

Conclusion

We

had several underlying theories governing the behavior of the carts. The first

was the conservation of momentum. Our data suggested without reasonable double

that momentum was conserved. The second theory, conservation of kinetic energy,

was disproved. As expected, in all runs kinetic energy was released (negative)

because there was defamation in at least 1 can every time (which was obvious

from the inelastic behavior). The last theory, that of the linear relationship

between total deformation and kinetic energy, was an indirect one based on the

sign value for kinetic energy decreasing (getting increasingly negative) as

deformation went up. That was also expected and backed up the assumption that

the more the cans were crushed, the more kinetic energy had to have been

released.

Remarks

The

experiment itself was a fascinating conclusion to the weeks of work did on

collisions and the conservation laws. I was impressed with how simple the

actual trials were compared to the wealth of data and variables that lay

beneath the collisions. This lab offered not just a recapitulation of the

concepts we already were familiar with, but made us think about what those

principals meant abstractly.